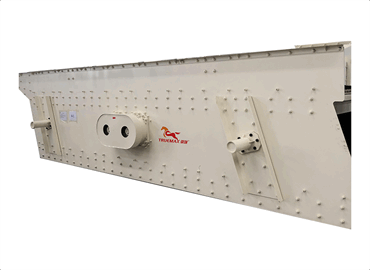

YA Vibrating Screen

Introduction:Using the structure of small amplitude, high frequency and large inclination angle, so that the machine has high screening efficiency, large processing capacity, long life, low power consumption and low noise

Product Details

PRODUCT INTRODUCTION

The circular vibrating screen adopts cylindrical eccentric shaft exciter and eccentric block to adjust the amplitude. The material sieve has a long flowing line and many screening specifications. It is specially designed for quarrying materials in quarries. It can also be used in mines, coal preparation, and mineral processing. , Building materials, power and chemical departments are used for product class巾cation, with reliable structure, strong excitation force, high screening efficiency, low vibration noise, ruggedness, convenient maintenance, safe use and so on.

WORKING PRINCIPLE

The Motor use a triangle belt make the vibration exciter of eccentric block at a high speed to rotate , so that it will form a strong centrifugal force and do circular motion of a certain amplitude. The screen of materials through the screen box do pulse transmission on inclined screen surface , and produce a continuous throwing action. When the materials pass through the screen surface , the particles smaller than the screen hole can pass through the screen mesh to achieve screening.

PRODUCTION ADVANTAGES

1.Using block eccentricity as excitation force, strong excitation force

2.The screen beam and screen box adopt high-strength bolts, with simple structure and convenient and quick maintenance.

3.Using tire coupling, flexible connection, stable operation.

4.Using the structure of small amplitude, high frequency and large inclination angle, so that the machine has high screening efficiency, large processing capacity, long life, low power consumption and low noise |

Parameters Table

| Model | Screen mesh layer | Screen hole dimensions (mm) | Feed port dimensions(mm) | Handing ability(m³/h) | Dulble vibration amplitude(mm) | Motor Model | Power(kW) | Screen mesh dimensions(mm) |

| 2YA1548 | 2 | 3~100 | ≤300 | 22~150 | 8 | Y160L-4 | 15 | 1500×4800 |

| 3YA1548 | 3 | 3~100 | ≤300 | 22~150 | 8 | Y160L-4 | 15 | 1500×4800 |

| 2YA1848 | 2 | 3~100 | ≤300 | 32~276 | 8 | Y180M-4 | 18.5 | 1800×4800 |

| 3YA1848 | 3 | 3~100 | ≤300 | 32~276 | 8 | Y180M-4 | 18.5 | 1800×4800 |

| 2YA1860 | 2 | 3~100 | ≤300 | 65~586 | 8 | Y180M-4 | 22 | 1800×6000 |

| 3YA1860 | 3 | 3~100 | ≤300 | 65~586 | 8 | Y180M-4 | 22 | 1800×6000 |

| 2YA2060 | 2 | 3~100 | ≤300 | 100~400 | 8 | Y200L-4 | 18.5 | 2000×6000 |

| 3YA2060 | 3 | 3~100 | ≤300 | 100~400 | 8 | Y200L-4 | 22 | 2000×6000 |

| 2YA2070 | 2 | 3~100 | ≤300 | 100~480 | 8 | Y200L-4 | 22 | 2000×7000 |

| 3YA2070 | 2 | 3~100 | ≤300 | 200~480 | 8 | Y200L-4 | 30 | 2000×7000 |

| 2YA2270 | 2 | 3~150 | ≤300 | 200~550 | 8 | Y200L-4 | 30 | 2000×7000 |

| 3YA2270 | 3 | 3~100 | ≤300 | 200~550 | 8 | Y200L-4 | 30 | 2000×7000 |

| 2YA2460 | 2 | 3~150 | ≤300 | 90~810 | 8 | Y225S-4 | 37 | 2400×6000 |

| 3YA2460 | 3 | 3~150 | ≤300 | 90~810 | 8 | Y225S-4 | 37 | 2400×6000 |

| 2YA2570 | 2 | 3~150 | ≤300 | 250~650 | 8 | Y200L-4 | 30 | 2500×7000 |

| 3YA2570 | 3 | 3~150 | ≤300 | 250~650 | 8 | Y200L-4 | 30 | 2500×7000 |

Customer case